Product classification

Metallic Gaskets

-

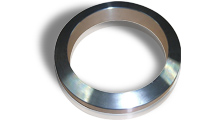

Ring Joint Gasket

Ring Joint Gaskets are widely used in oil, petroleum and chemical process fields. Precision machined, metallic sealing rings suitable for high pressure and high temperature applications.

-

Lens Gaskets

Lens Gasket is a line contact seal for use in high pressure piping systems and in pressure vessel heads. The lens cross section is a spherical gasket surface and requires special machining on the flanges. Since the contact area is very small and gasket seating pressures are very high, the gaskets will seat with a small bolt load.

-

Solid Copper Gasket

Single use seal on ultra high vacuum flanges. Copper solid gaskets fit between the same size UHV/CF flanges to make a impermeable seal. Copper is relatively soft, the steel knife edges of the flanges bite down on the copper as the flanges are tightened toward each other.

-

Copper Exhaust Gasket

Designed to provide excellent sealing and durability. Fabricated from high quality material. Heat resistant as well as reusable. Features a precision die cut. Backed by a limited warranty.

-

Lens Ring Joint Gasket

> Lens ring joint used in higher pressure then 3,000 lbs. > These gaskets had been used on pipe flanges in synthesizing line.

-

BX Ring Joint Gasket

> Although similar in style to the octagonal ring joint > BX series can only be used with 6BX flanges > BX rings for higher pressure rating starting at 5,000 lbs, and ending with 20,000 lbs. > Rings can not be re-used.

-

RX Ring Joint Gasket

> Ring Joint Gaskets are for oilfield and process industry duties. > RX gaskets are designed for pressures up to 15,000 PSI. > RX types of gaskets are more costly then Oval and Octagonal rings. > RX type gaskets perform excellent in API 6B flanged.

-

Octagonal Ring Joint Gasket

> Ring Joint Gaskets are for oilfield and process industry duties. > Octagonal shape gasket is belong to API 6A R series > These gaskets are used in pressures up to 10,000 PSI, more than Oval ring joint. > The oval type is the only gasket that will fit a bottom radiused groove. > Gaskets and not re-used after torque.